Tasmanian Oak Properties

E.regnans, E.obliqua, E.delegatensis

For further information click tables marked

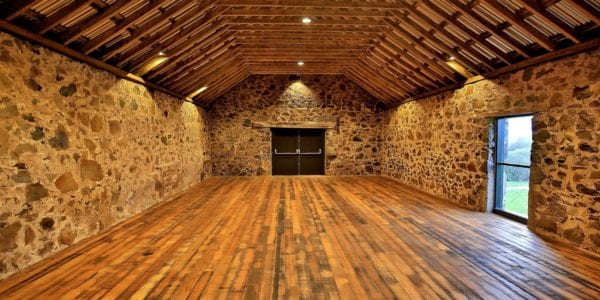

Availability & Appearance

General Availability

Readily available and continuously harvested.

Appearance Grade

Available

Plantation

Not available

Structural Grade

Available

Veneer

Available (multiple thicknesses)

Sizes

Dressed seasoned timber 40 to 285mm wide by 12 to 40mm thick. Undressed seasoned timber 50 to 300mm wide by 19-50 mm thick. Lengths up to 5400mm long are available, with the bulk of production between 2700 and 4200mm long.

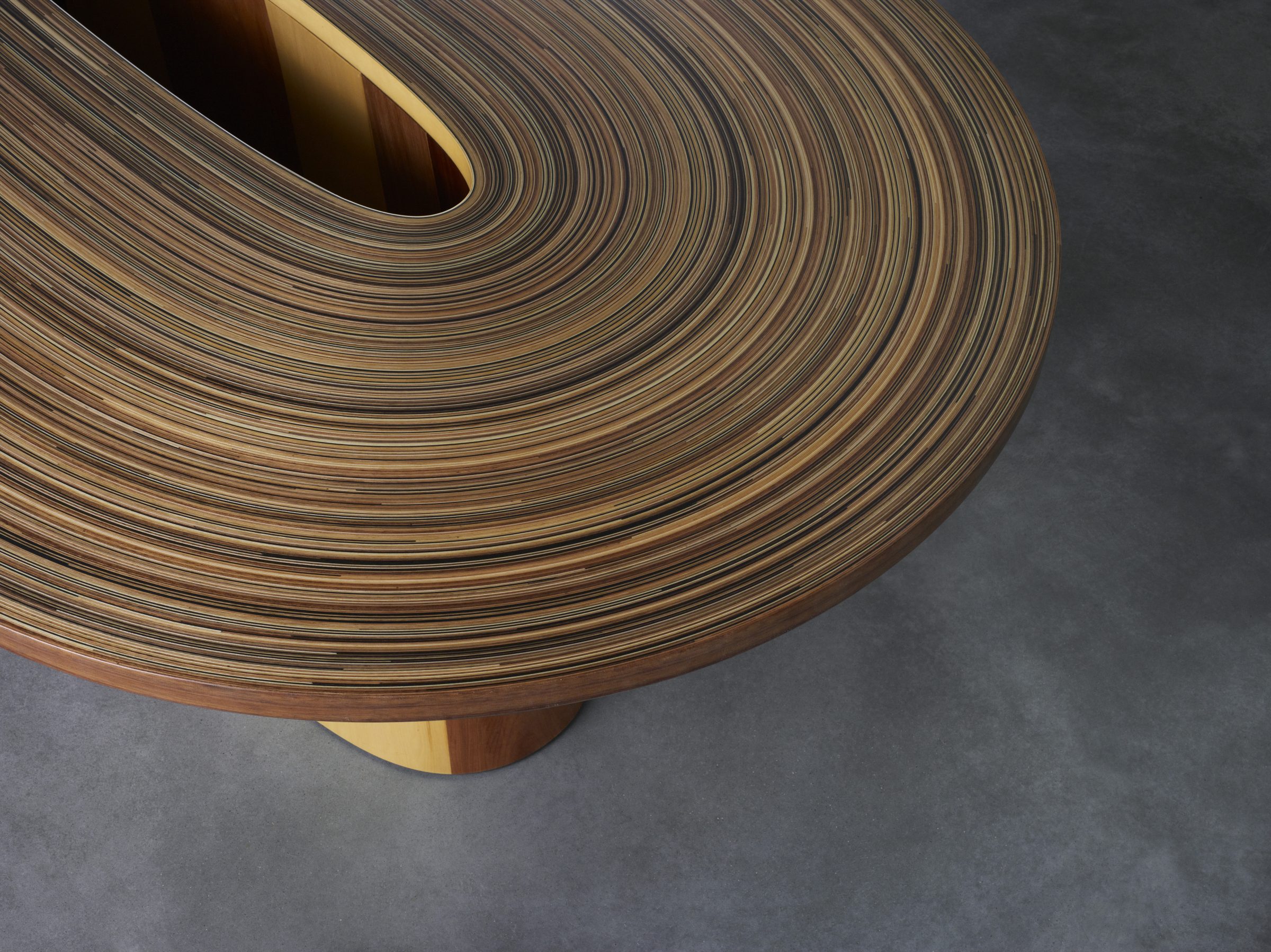

Colour

Straw to reddish brown with intermediate shades of cream to pink.

Grain

Grain is usually straight, open and even. Occasionally coarse-grained or fiddle backed. Growth rings are visible and usually conspicuous.

Texture

Uniform and smooth.

Density

Unseasoned

Seasoned

Density (per standard)

1050 kg/m3

650 kg/m3

Durability

Above-Ground

Class 3: 7-15 yrs

In-Ground

Class 4: 0-5 yrs

Susceptible to Lyctid Borer

Yes

Marine Borer Resistance

0-20 yrs

Termite Resistant

No

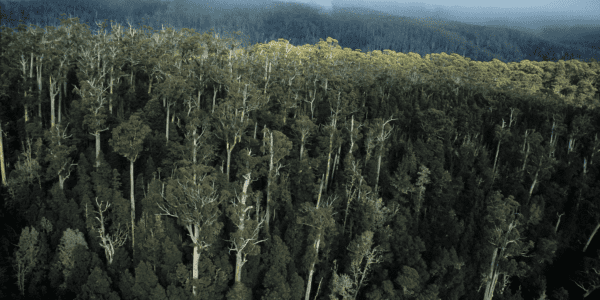

Environmental Details

Resource

Native - Wet Eucalypt and Dry Eucalypt

Reserves

35% of the total Tasmanian Oak forest types are reserved.

Certification

Available

Chain of Custody

Available

Carbon Storage

308 kg/m3

R Values

0.57 (100mm)

Fire Properties

Average Specific Extinction Area

< 250 m2/kg

Bushfire Resistance

BAL-12.5

Critical Radiance Flux - Higher

> 2.2 < 4.5 kW/m2

Critical Radiance Flux - Lower

> 2.2 < 4.5 kW/m2

Smoke Development Rate

< 750% per min

EFH Ignitibility: 6

EFH Smoke-Develop Index: 3

EFH Spread-of-Flame Index: 5

Fire Properties Group Number: 3

Joint

Unseasoned

Seasoned

Joint Group

J3

JD3

Mechanical Properties

Unseasoned

Seasoned

Hardness (Janka)

4.2 kN

5.7 kN

Impact

14 J

21 J

Maximum Crushing Strength

30 MPa

63 MPa

Modulus of Elasticity (MOE)

13 GPa

17 GPa

Modulus of Rupture (MOR)

63 MPa

110 MPa

Toughness (IZOD)

15-24 Nm

15-24 Nm

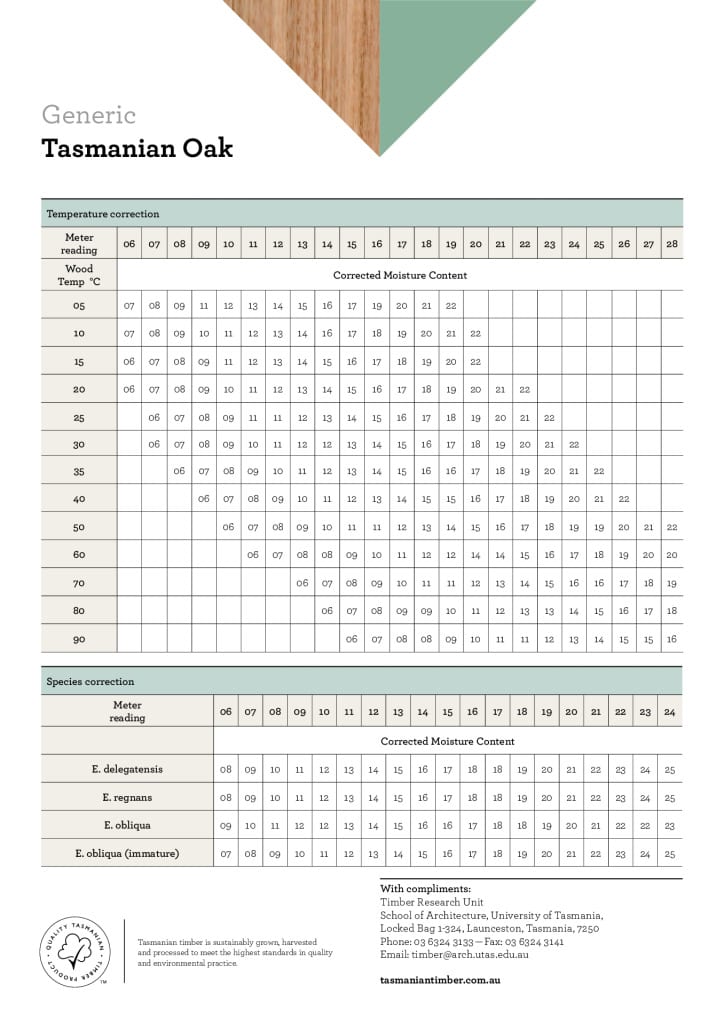

Movement

Radial

0.36% per 1% MC change

Tangential

0.23% per 1% MC change

Shrinkage

Radial

3.5%

Tangential

6.5%

Stress

Unseasoned

Seasoned

Common Structural Grades

Structural #3: F8

Structural #2: F17

Structural Grades

S1:F14, S2:F11, S3:F8, S4:F7, S5:F5

S1:F22, S2:F17, S3:F14, S4:F11, S5:F8

Strength

Unseasoned

Seasoned

Strength Group

S3 & S4

SD3 & SD4

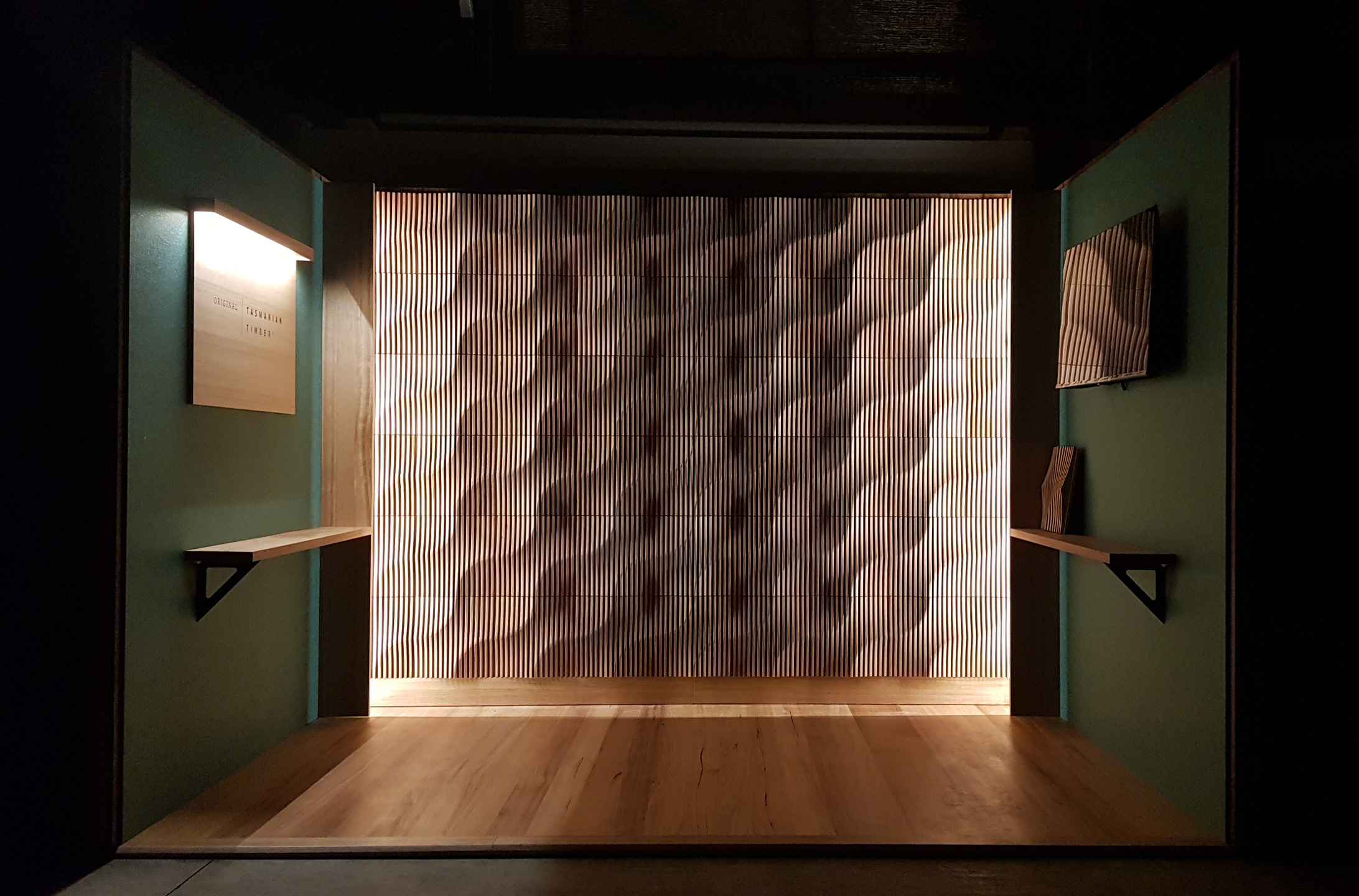

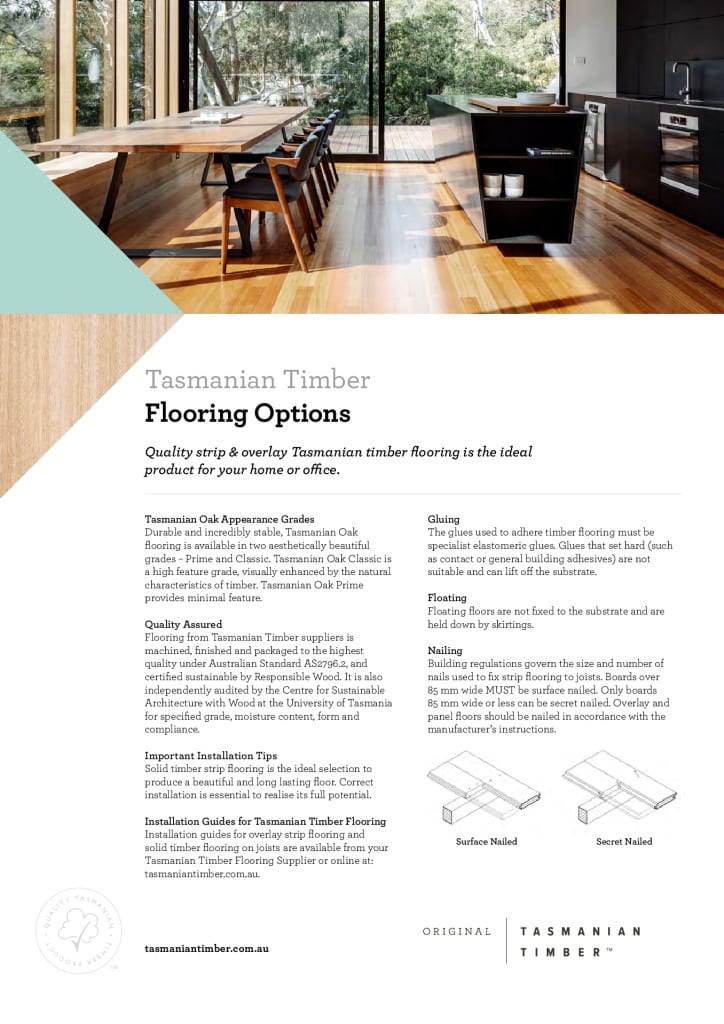

Workability

General Workability

Highly resilient and relatively easy to work.

Bending

A good to fair bending timber. 25mm material bends reasonably well to radius of 100mm.

Blunting

Moderate. Can be severe in dense material.

Boring

Easy to drill. Holes are usually clean and to size.

Finishing

Readily worked to a smooth, lustrous surface. Most finishes adhere very well. Stains very well.

Gluing

Glues satisfactorily with most common adhesives.

Moulding

Surfaces are true and clean, even-end grain. Holds edges well.

Nailing

Pre-drilling is often necessary in seasoned or denser material. Nails hold well.

Planing

Moderate feeding force is required. Surfaces very smooth and lustrous when working 'with' the grain.

Rebating + Mortising

Generally produces excellent results.

Sawing

Cuts fairly cleanly with moderate feeding force.

Turning

Turns well with sharp arrises.

Sources: Centre for Sustainable Architecture with Wood (CSAW), Wood Solutions