Tasmanian Veneer – uniformity or inimitability? The Specifiers ‘lolly-shop’

Tasmanian veneers have long been sought after for a variety of applications with some stunning examples of the capability of the product in beautiful furniture and custom doors and cabinetry.

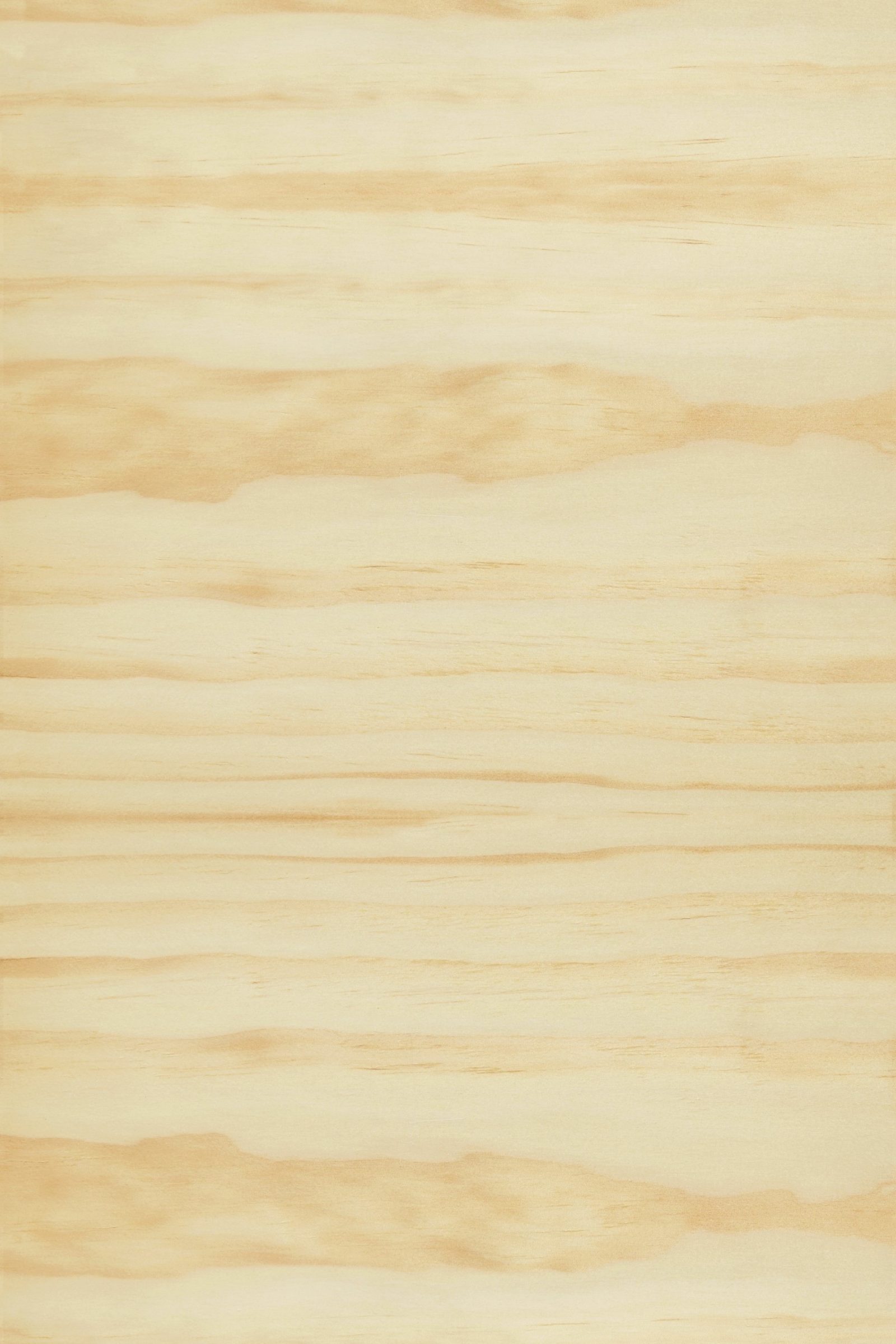

Veneer has traditionally been revered for its uniformity. The matchless repetition created by thinly slicing timber from one larger piece was sought after for cabinetry and linings, particularly in large commercial fitouts.

Veneer is capable of covering vast expanses with a consistent look. It is assembled into a sheet or layon which is adhered to a sheet material such as MDF or a more malleable substrate.

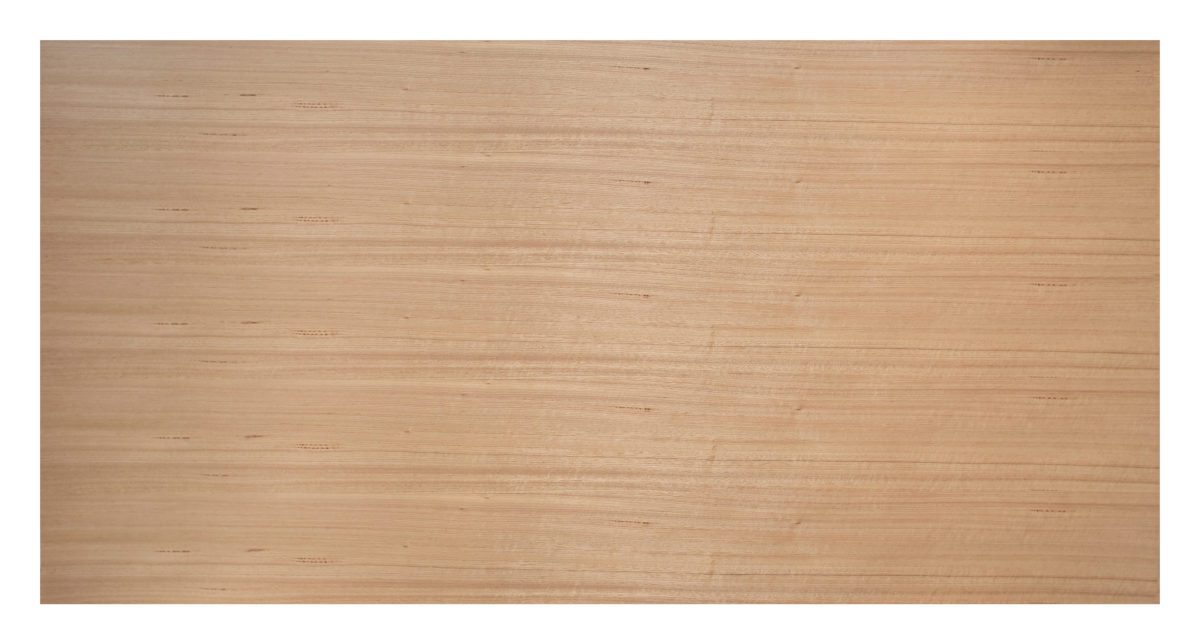

Veneer is then often matched with solid-sawn timber of the same species in furniture, joinery and lining – giving a seamless colour palette.

Today, veneer is rising in popularity for its ability not to blend in, but instead to be different.

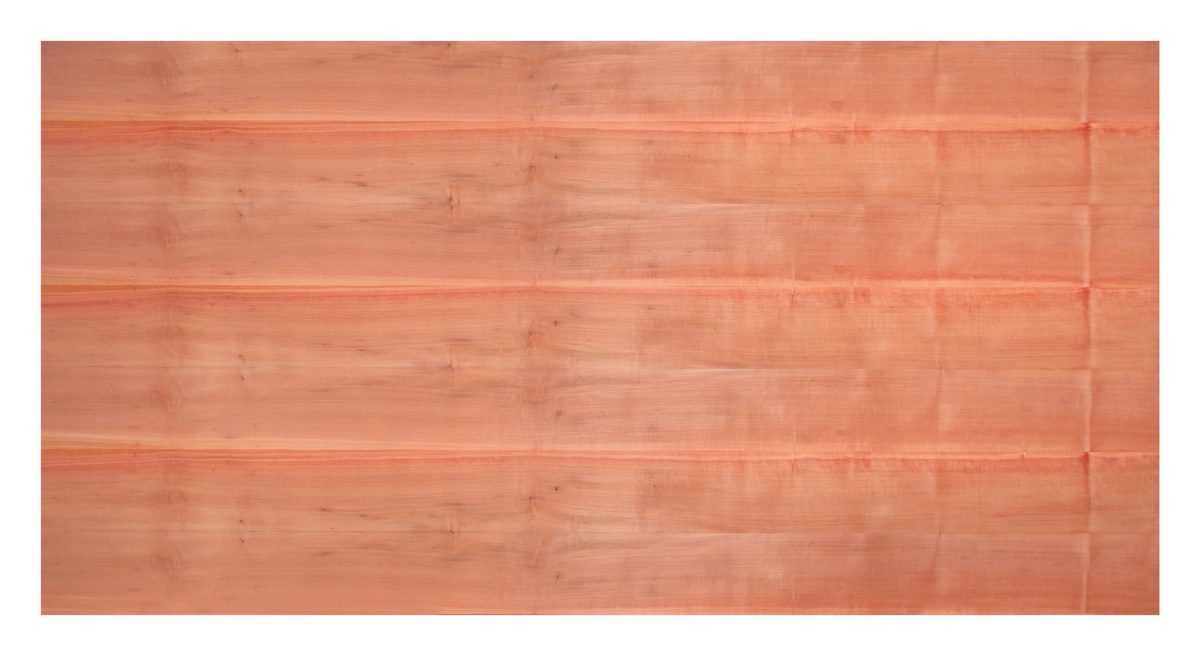

Hotels are lining guest room ceilings with distinctive combinations of Black Heart Sassafras, while others are setting themselves apart with oversized bed heads created with almost floor to ceiling Blackwood.

And it’s little wonder. When faced with stacks of veneer sheet in endless colour and grain variations, it’s impossible not to wonder how the Birdseye Huon Pine would look behind your bed, or the Black Heart Sassafras Wild would look on the front of a kitchen bench.

If ever there was an appropriate metaphor for a kid in a lolly shop – a specifier in a veneer shop would surely be it!

This versatile product can be cut and assembled into almost unlimited pattern combinations.

“There’s tremendous artistic availability in veneers,” says Michael Lee, Technical Officer at the Centre for Sustainable Architecture with Wood.

“All Tasmanian timbers are available as veneers with ample availability in both sheets and in layons including thick veneers, standard veneers or full-size sheets,”

“And, our suppliers are able to book match and match coatings with different veneers to deliver some really beautiful and unique products.

Tasmanian veneer is available in an extensive range of species, grades, grain, colour and pattern variations.

Treating the species with care by maximising recovery

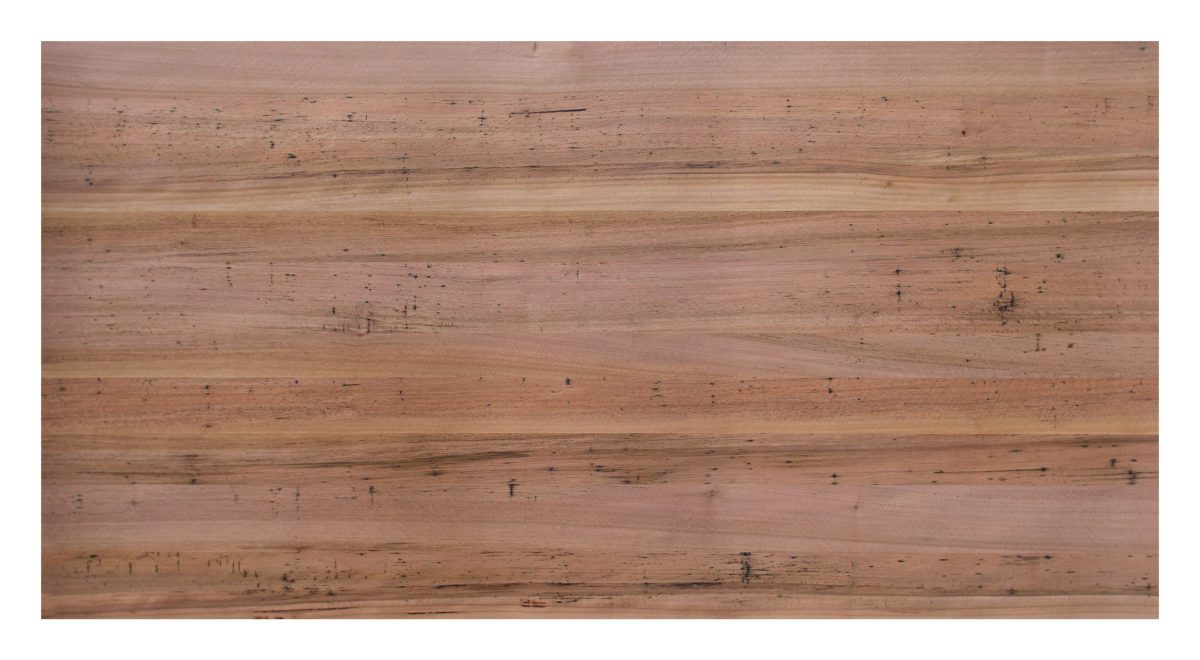

Lee says, in addition to the design benefits of veneer, there is an environmental benefit as well.

“One of the biggest advantages of veneers is that we’re able to stretch the resource, getting the available recovery into the more square footage of available material,” he says.

“This is especially important when we’re dealing with minor species that need to be treated with care to ensure the most is being made out of the material.”

“Blackheart Sassafras is a typical example of a minor species, which is fairly limited and only occurs naturally. We’ve tried to recreate the unique figuring that’s found in this species, but we haven’t been able to replicate what happens in nature.

“Using Blackheart Sassafras as a veneer is a great way of getting the look of the species on a large scale from a small volume of material”.

“For a special species like Fiddleback Blackwood, which occurs naturally as a result of things like growth stresses but only appears in around 5% of the material harvested, veneer is a great option.”