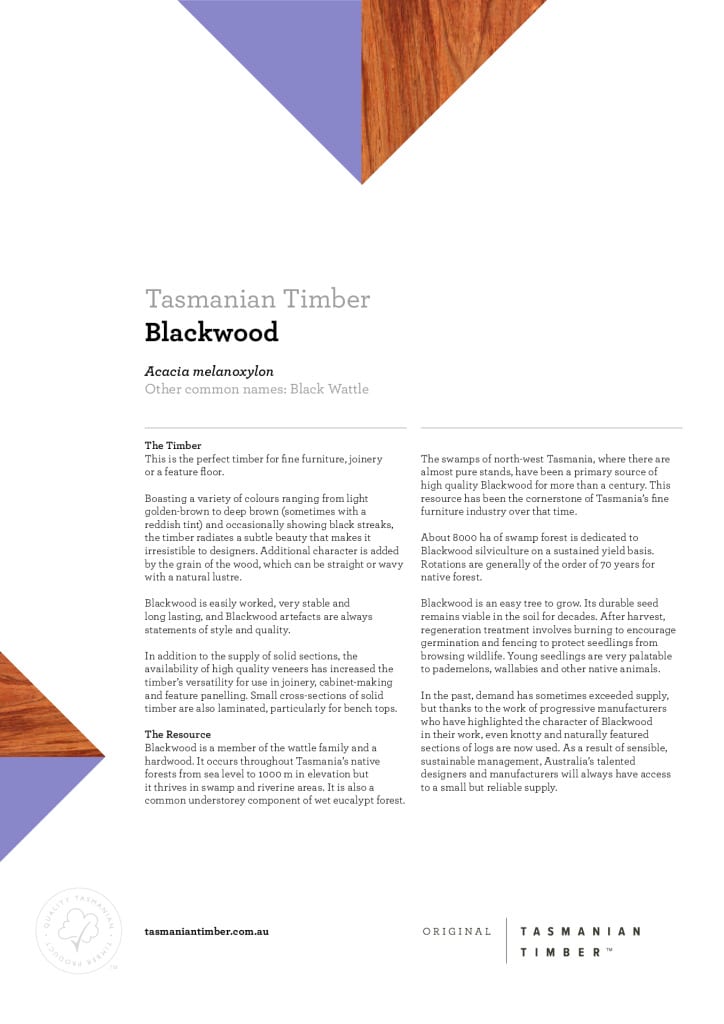

Blackwood

Blackwood is the perfect timber for fine furniture, joinery or a feature floor, radiating a subtle beauty that makes it irresistible to designers. High-quality veneers are used in joinery, cabinet-making and feature panelling.

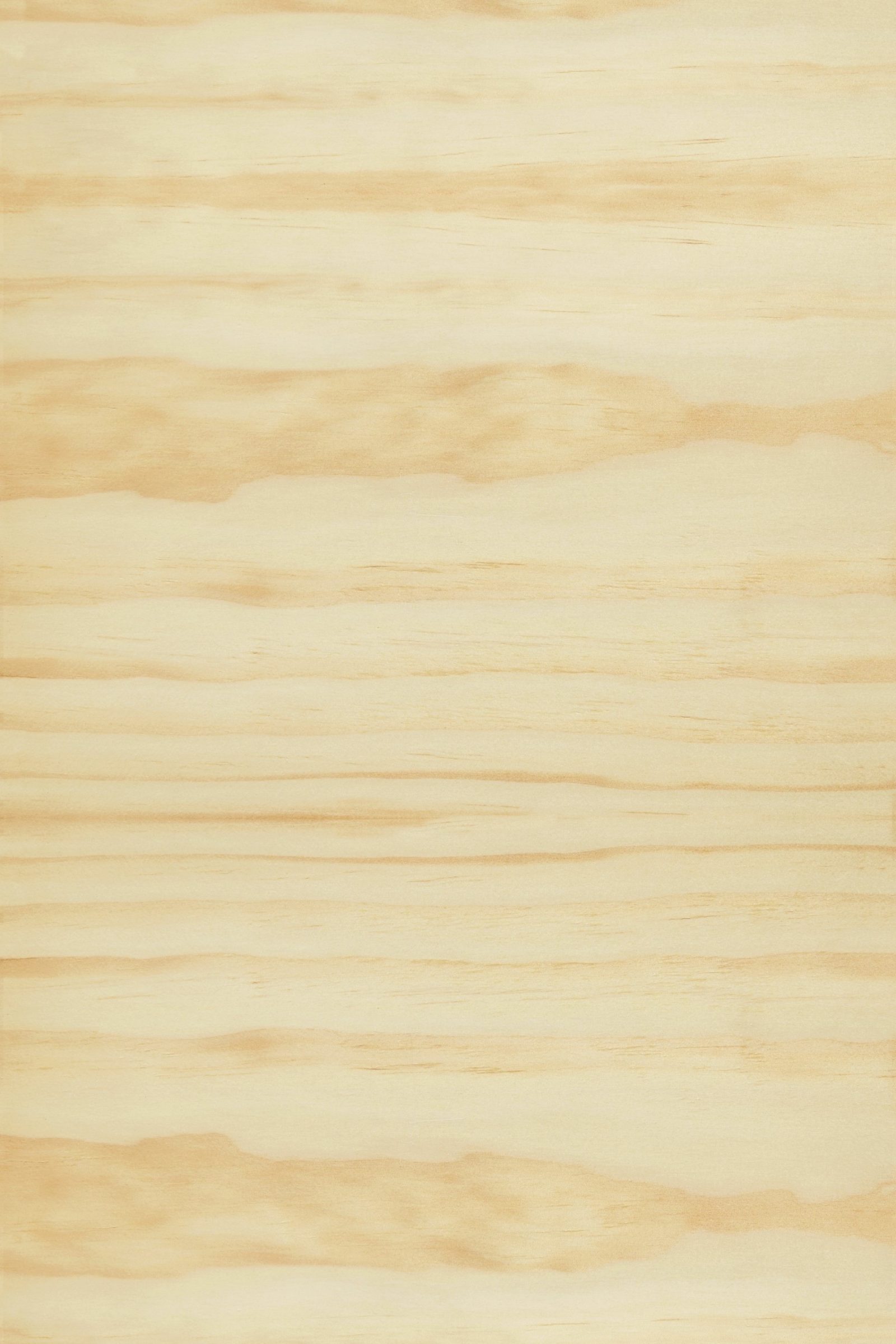

Boasting a variety of colours ranging from light golden-brown to deep brown (sometimes with a reddish tint) and occasionally showing black streaks, the timber radiates a subtle beauty that makes it irresistible to Tasmanian designers. Additional character results from the grain of the wood, which can be straight or wavy with a natural lustre.

Blackwood is easily worked, very stable and long lasting, and blackwood artefacts are always statements of style and quality.

In addition to the supply of solid sections, the availability of high quality veneers has increased the timber's versatility for use in joinery, cabinet making, and feature panelling. Small cross sections of solid timber are also laminated, particularly for bench tops.