Timber Veneer Association of Australia Tours Tasmania

The Timber Veneer Association of Australia’s (TVAA) members have recently returned home from a Veneer Manufacturing tour of Northern Tasmania. Association members, who include some of the country’s leading furniture, component manufacturers and timber veneer manufacturers left with a thorough understanding of production and environmental credentials of Tasmania’s veneer industry, and an appreciation for the complexity and value of the sector.

Thirty-five TVAA members were guided by Shawn Britton and TVAA President Anthony Wardrop to Britton Timbers sawmill in Smithton, Britton Timbers Plantation Forest just outside of Smithton, Cusp Building Solutions and Britton Timbers Veneer Mill in Somerset.

Participants were shown through various manufacturing processes involving the processing of logs; sawing, drying and profiling at the Smithton Mill, witnessing Tasmanian Oak and Tasmanian Blackwood being processed by highly skilled operators at the mill. This was followed by a visit to a plantation site where they learnt more about the regeneration of plantation forests and the care and maintenance of trees throughout their lifecycle through to harvest. They learned that techniques such as cold burning forests and pruning and thinning of forests proved vital in the health and well-being of the forest.

“The sheer time it takes to regenerate timber and properly season it ready to manufacture was the big takeaway here,” said TVAA Secretary Evan Danahay.

From Smithton the tour moved to Cusp Building Solutions where General Manager Michael Lee took the TVVA members through the processing and construction advantages of Cross Laminated Timber utilising Tasmanian Plantation Oak, which is often destined for pulp/ paper.

“With state-of-the-art equipment and long-established European manufacturing techniques, tour participants received an education in the environmental advantages of using sustainably sourced timber in modern construction in lieu of traditional, carbon-heavy materials such as concrete and steel. This was a big eye-opener as to where the construction industry is heading and the involvement of timber,” said Danahay.

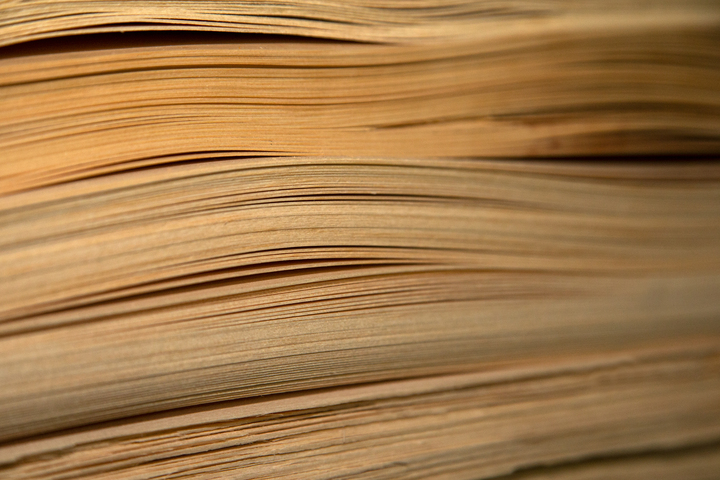

“We finished our day at Britton Timbers veneer mill in Somerset. Here we witnessed various Tasmanian species of timber veneer being sliced, dried, joined and pressed onto panels ready to be sent off to their new home as joinery, wall and ceiling panels as well as furniture,” said Danahay.

“Our cabinet and furniture makers really gained a new appreciation for the materials they use every day and the sheer amount of care and processing involved before it meets their factories for further manufacturing,” said Danahay.

Leading Australian manufacturer Simon Bowler, from Silver Lynx in Victoria, was a guest on the tour. Silver Lynx manufactures bedroom furniture for Australia’s four biggest bedding retailers – Snooze, Harvey Norman, Domaine and 40 Winks. Simon joined the tour to better understand the product and process of making veneer, beginning with how the forests are managed so that he can relay this to his discerning customers.

“Our customers want to know about the sustainability of our products. Their QA programs are rigorous. We need to be QA certified,” says Bowler.

“It is such a great story here in Tasmania. Tasmanian Timber veneer is a 100% sustainable product,” says Bowler.

“They are adding great value from end to end. They’re managing the forest well both regrowth and plantations.

Bowler was surprised about just how much work goes into managing the forests.

“These are the best timbers in the world. Why wouldn’t you add value to them? The industry has a bright future.

Bowler explains that the sustainability of supply is also critical to the TVAA’s members’ businesses.

“We need a reliable supply. It is critical to our business. If we’re going to invest in capital, we need surety of supply. The availability of Tasmanian veneers is great. They are doing a great job in the mill. They have our custom specification down pat”.

Belinda Hovell from Worldwide Timber Traders said Tasmania has the only veneer-slicing mill in Australia and she wanted to see and understand the process from the log to the veneer layon.

“There is so much that happens before the slicing that I didn’t understand. From Brittons log selection to squaring it off, and then seeing the skill of the guys as it comes out of the machine and how they do it – that takes years of experience. Their knowledge was impressive and their passion for their job was evident. They all had smiles on their faces and enjoyed talking about it and explaining their role in the process.”

Hovell said they’d like to get everything from Tasmania, but there isn’t enough resource to supply all their needs.

“We have no choice but to bring it in from overseas – particularly when specified by architects. But if our customers want the most sustainable product, we recommend Tasmanian timber and veneer every time,” said Hovell.

“It does influence the decisions that our customers make. It was great to learn about the lengths Britton Timbers go to make the process as sustainable as possible.”

Hovell explained that the mill mismatch their veneer so that 90% of the log is used instead of the more traditional grain-matched layons so there is very little material left. The residues from the process are then supplied to the local McCain Vegetable factory, the local swimming pool and other businesses to heat their boilers, and produce their energy, nothing is wasted.

“It’s a beautiful circular economy. Everyone is thinking about how to keep the waste down and how to make everything else better. It’s huge from an environmental and sustainability perspective.”

The tour also explored the local production forests to better understand where the veneer resource comes from.

“We went to a plantation where the trees were 13 years old and then a natural forest where the trees were 30 years old. To visually see how long it takes to grow a tree – I don’t think people quite understand. The importance of regrowth and keeping the resource going is critical. Tassie has got that right for sure. It’s very impressive to see.”

Worldwide Timber Traders create pressed boards for cabinet makers, installers and construction companies. The TVAA held its committee meeting during the tour at the recently refurbished Cradle Coast campus of the University of Tasmania, which is full of Tasmanian Oak veneer products.

“Visually it was very appealing,” said Hovell, “But what really struck me was that this campus is teaching the next generation of doctors and nurses in this beautiful architecturally designed space. This product is part of the growth of the area.”

TVAA Secretary Evan Danahay said the Cradle Coast campus is very significant site for the TVAA, given the design and heavy influence of timber and timber veneer throughout.

“We were treated to a guided tour of the site by Pro Vice-Chancellor Jim Cavaye, who elaborated on the strict design brief of using only locally sourced, sustainable materials whilst outlining the campus objectives around nursing, student retention and the campus’s engagement with the community.”

Both Hovell and Bowler said the TVAA tour was a very worthwhile experience, they would join again and send other team members to experience the provenance of the veneer products from Tasmania.