From round logs to high end architectural products: Josh Turnbull on timber processing

Timber is in Josh Turnbull’s blood. Josh’s great grandfather, grandfather and uncles were sawmillers. Growing up in Geeveston, a town in southern Tasmania on the edge of the forest, everyone is his family was involved or connected to the sawmilling industry in some way.

Josh has now worked in the industry for 20 years from the family business to stacking green boards on the floor at the Neville Smith Forest Products (NSFP) Southwood Mill, to today being the Group General Manager of Production for the innovative NSFP timber company. Knowing the sawmilling industry from one end to the other, Josh was the perfect person to speak to the Original Thinkers Podcast about timber processing.

Josh says his grandfather’s experience in the industry is very different from sawmilling today, “it’s polar opposite, the sawmill established by the Neville Smith family is very innovative, has great equipment and takes all the manual handling aspect out.”

He says a lot of the older staff have the IP, and the younger generation have the hand, eye coordination. Together they have the knowledge and the technological knowhow to respect the product while maximising recovery from every log with state-of-the-art machinery.

“It’s all about optimisation of our resource, because every sawmill lives and breathes recovery, so trying to maximise the total yield out of that round log into a square product.”

From a round log to finished product

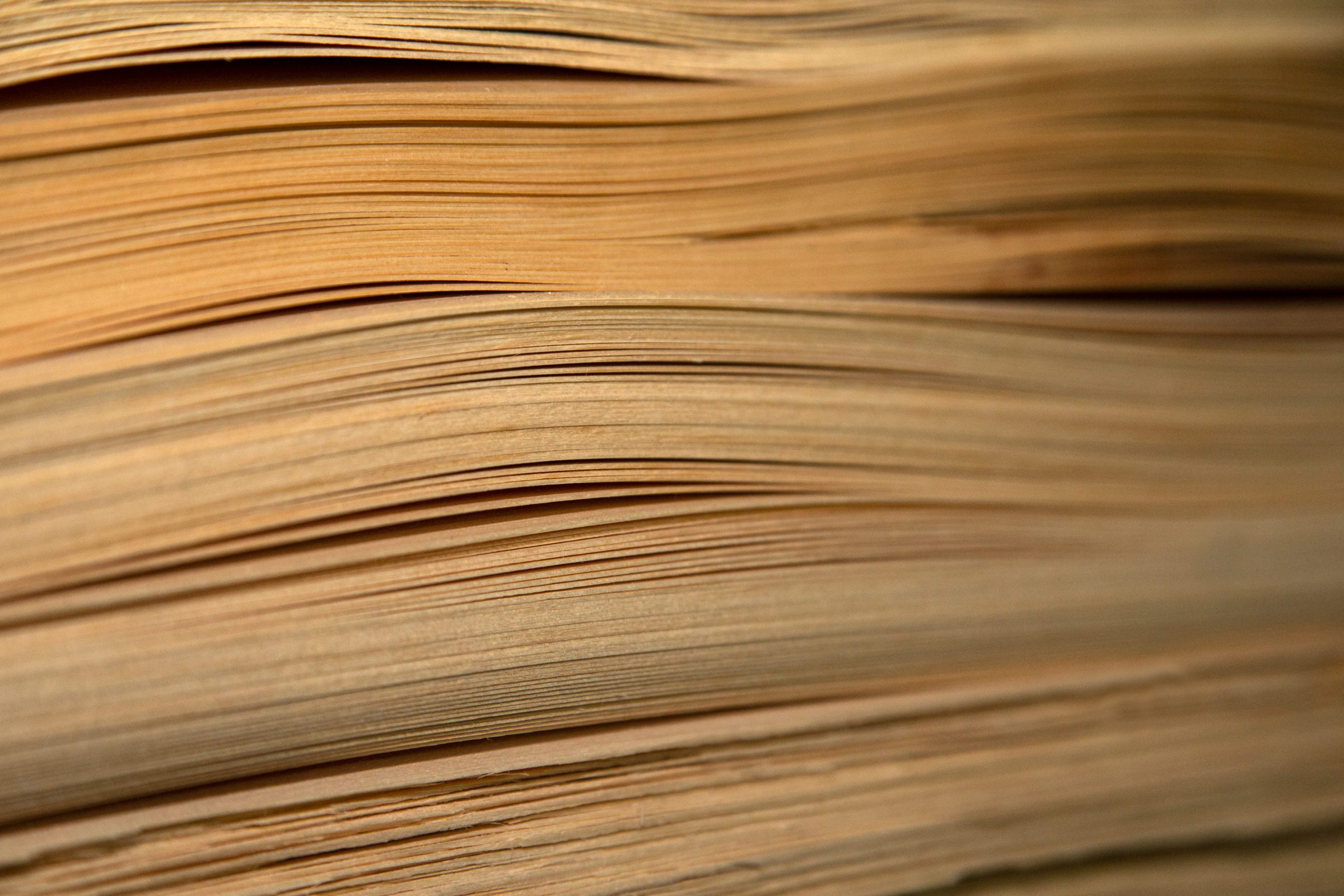

Josh talked through the difference between a green mill, a dry mill and the other systems that lead to the finished timber product. It comes straight from the forest, into the green mill where it is cut. The goal is to maximise the square recovery out of the round log.

“The green mill is the first stage. We take it in the round and we process it. About 90 percent of it will go on to be seasoned. We then go into a drying yard, which is located at our facility in Launceston. We then season the timber [the process of drying timber to remove the bound moisture contained in the walls of the wood cells to produce seasoned timber], what we’re trying to do is get the timber to a fibre saturation point. We take the wood down to a 21% moisture content. Then we can recondition it and dry it.”

The timber is racked in the yard. Most of the timber is there for about 12 months, and the thicker the timber the longer it is in the yard for seasoning. Before the timber goes into the kiln it is reconditioned. As Josh explains:

“Through the time out in the yard, you’ve got a bit of collapse, so the cell structure in the timber has changed form. So then we put it into a reconditioning chamber to pump it back up, and then it’s taken on a lot of moisture, and then we snap dry it back down to about 14%, in the final drying stages.”

The 14% moisture content is measured by probing. Josh says they have clear visibility throughout the whole drying process, so if there needs to be any changes during the drying cycle the team can do that. The finished product then gets audited by the Centre for Sustainable Architecture with Wood for moisture content, quality assurance and adherence to Australian standards. “We’ve got a great drying team up [in Launceston] they really take pride in what they do.”

Why are moisture levels so important?

Timber is a natural product and one of the desirable properties of timber is that it essentially breathes moisture in and out. However poor moisture content control can generate significant problems for builders, especially in appearance applications. Which is why NSFP is so meticulous with the moisture levels in their timber products.

They also provide installation guidelines for all their timber species and products. Josh also explained the importance of where the timber is installed:

“When you’re putting timber into any application, it needs to be acclimatised. I think it’s just about showing that natural product the respect that it needs, and if you let it settle into its new home, it’ll serve you for hundreds of years going forward.”

Woodsmith, Abelwood, Evolution Lining and Pellets Fires

In addition to being one of the largest suppliers of Tasmanian Timber, NSFP also supplies a range of architectural products including Abelwood Tasmanian Oak Flooring, Woodsmith Engineered Flooring, mouldings and Abelwood Evolution Lining.

“We do some very sleek, streamlined designs to underpin the architectural market. I think Ablewood and the Evolution Lining that we’ve put into the market are good examples of that. We continue to innovate, to keep up with architectural changes… It’s not just innovation, but getting more square metres out of every cubic metre [of timber].”

Woodsmith is an engineered flooring product and a favourite among architects. Woodsmith is used throughout the offices of award winning Australian architectural practice Fitzpatrick + Partners, by the University of Tasmania and throughout the National Portrait Gallery.

“We’ve also been lucky to be involved in a lot of high end basketball courts with our sport flooring. And we love doing that. Especially in my facet of the business, seeing the tree all the way to the seasoning, to the processing, and then going into the install. It’s a great story to be able to go and watch a game on a product that you’ve supplied.”

In his grandfather’s day the waste timber would end up in landfill, but with the installation of two high end Italian Nova Pellet mills, NSFP has closed the loop to have minimal to zero waste in their business. Josh explained that there has been a huge amount of research into the bio energy emissions.

“It just really stacks up. It’s a very clean form of heating.”

Sustainability and Supply

When asked about the sustainability of the timber harvested by NSFP and the supply, Josh said the Tasmanian Oak products are regrown through a sustainable forestry process, harvested by STT, and certified by PEFC and that NSPF has 100% chain of custody for all of their products.

“We can define the origin of a coupe, all the way from the standing, to felling, to receiving. And then we can tell our customer, at any time through the process, from implementation at the start, where the logs were originated from, what packs they came out of, and all of the processes they’ve touched. Every log is barcoded from STT. That process is rigorous and it really works well.”

Josh said it’s become very, very important to be able to communicate this process to assure their customers of the sustainability of the product. The other question customers have is about the supply of Tasmanian Timber going forward.

“We’ve definitely seen a bit of ambiguity around supply or continuity of supply with the exit of the Victorian forest in the native space. I can assure you that the supply in Tassie is great now and into the future. And obviously we’ve got the estates of the plantation yields coming online in the very near future.”

“It’s readily available and it is very, very sustainably harvested”