Assessing Quality and Durability When Specifying Timber Flooring

Naturally warm and attractive, timber remains among the most popular choices for flooring. One of the world’s oldest building materials, timber’s physical properties and potential for sustainability are highly regarded. Combining premium aesthetics with durability, timber has been a reliable choice for interior applications for centuries. It is also eco-friendly, being less emissions-intensive and more sustainable over its lifecycle than other building materials like steel and concrete. However, when specifying timber for specific applications, the varying properties of different species must be taken into account.

Setting aside the wide range of choices for colour and price, there are other factors to consider such as durability, toughness, and a long lifespan when choosing a species for particular flooring purposes. Flooring quality is often perceived to be directly correlated to its Janka rating – the flooring industry’s standard for comparing the timber’s hardness. While it is widely used by industry professionals, there is growing awareness of the limitations of the Janka rating, including the fact that dent resistance is only one aspect of floor durability. Flooring must meet a range of performance requirements, and hardness (or indentation resistance) is only one factor. Stability, that is the timber’s ability to resist dimensional change that can result in warping and splitting, is an important consideration. Scratch resistance, repairability, appearance and ease of maintenance also contribute to the longevity of a flooring solution. In this whitepaper, we take a look at the Janka rating and consider how it relates to other performance criteria for timber flooring. In doing so, we provide guidance on how this impacts specification for different flooring applications.

What is the Janka Rating?

The Janka hardness test is the rating used by the flooring industry as an indicator of wood’s resistance to denting. It was invented in 1906 by Gabriel Janka, an Austrian wood researcher, and later standardised by the American Society for Testing and Materials (ASTM) in 1927. The test for determining the Janka rating involves calculating the force required to embed an 11.28mm diameter steel ball halfway into a sample of wood.1

In Australia, the results of the Janka test are expressed as newtons (N) or kilonewtons (kN). The closer the Janka rating is to zero, the softer the wood is according to the scale, whereas a higher rating correlates with a harder wood. For example, balsa wood, a wood commonly used for crafts, has a Janka rating of 0.298kN and would be too soft for flooring applications. In comparison, Tasmanian Oak, a commonly used flooring timber, has an approximate Janka rating of 4.9-5.5kN.2 Brazilian Walnut (16.37kN) and Grey Box (15kN) are on the higher end of the scale.

The Janka rating is valued because hardness is commonly associated with how easily the timber flooring material will wear. “Softer” timbers are easier to indent, scratch, and wear over time, whereas hard timbers are perceived to be more “durable”. A Janka rating between 4-8kN, referring to medium density timbers, is considered by some flooring companies as the range suitable for flooring applications.3 Other companies advise against specifying any wood that has a rating of below 5.5kN.4

Limitations of the Janka Rating

Inaccurate ratings for mixed species

The Janka rating has limitations with hardness accuracy because it uses the lowest common denominator in the species mix as the measure. For example, Tasmanian Oak is a mix of three different eucalypt species: Eucalyptus Regnans, Eucalyptus Obliqua and Eucalyptus Delegatensis. The lowest portion of the species mix, that is E. Regnans, also has the lowest Janka rating (4.9kN), when in fact most of Tasmanian Oak is made up of E. Obliqua, which has a much higher hardness rating (7.4kN). Accordingly, the relatively middling Janka rating of Tasmanian Oak is misleading.

The reality is that Tasmanian Oak is one of the most widely used flooring timbers in Australian history. These floors have lasted for hundreds of years and have stood the test of time. This performance in situ and over time is a reliable indicator of this timber species’ suitability, longevity and durability in many applications.

Indentation resistance is only one aspect of floor durability

The Janka rating is primarily designed to test a floor’s susceptibility to denting. The test however does not reflect how the floor holds up against scratching, daily wear and tear and fluctuating environmental conditions such as temperature, moisture, and humidity changes. Other factors like scratch resistance, appearance, stability, and ease of maintenance contribute to a floor’s overall durability. A floor that balances all these properties is more desirable and practical to consumers than hardness alone.

A timber floor can be too hard

Some of the most appealing characteristics of timber flooring are its warmth, softness and spring under foot. A wood that is too hard may feel more like concrete when walked upon.

Specifying for Quality – Beyond Janka

Performance criteria for flooring

Floors must satisfy a range of performance requirements, which align with the specific application and installation conditions. Below is simplified performance criteria for long-lasting timber flooring:

- Appearance. Timber should be expected to have variations in grain and colour. A timber floor’s colour may change when exposed to sunlight. Factors such as species, finishing, and levels of sun exposure (direct or indirect) can impact how the floor will look over time.

- Moisture content and stability. It is important to know how the floor will perform in different environmental conditions. Changes in moisture and humidity can cause dimensional changes in wood. Different timber species exhibit different levels of dimensional variation.

- Indentation resistance. This property correlates to the Janka rating as discussed above. It is of high priority for floors that experience a heavy traffic load (such as in commercial or public spaces that are subject to the traffic of thousands of people per week), but this is not the majority of applications.

- Scratch resistance. Moving furniture and pets are some common causes for scratches on a floor. Wood hardness can give an indication of how resistant the floor will be to scratches, but the scratch resistance provided by the floor’s finish should also be considered.

- Finishing. The right choice in finishing will protect a floor from scratches, dirt and moisture, and also add it to its appearance. While all coatings will wear over time, some finishes are more durable than others, and also help preserve the timber.

- Workability and weight. If the wood is difficult to cut into shape, or is too heavy, it may add to installation time and costs. However, wood that is too soft or light may not provide sufficient durability.

- Repairability. The ease in which the floor can be repaired is an important consideration for owners as it will impact the cost of maintaining the floor over a long period of time.

Why is stability important for timber flooring?

The key consideration when specifying timber flooring is whether the material is fit for purpose. The differences in dent resistance between timbers on the “hard” to “very hard” range of the Janka scale will not matter if the floor is only subject to being walked on or the occasional movement of furniture. At the high end of the Janka scale, the levels of hardness being offered is generally not required for most applications.

Changes in atmospheric humidity will affect all end uses of wood. Humid conditions, subfloor moisture, leaks and spills are only a few of the occurrences that can cause disfigurement and warping of hardwood floors. Dimensional stability directly relates to how much the floor will experience movement in service, providing an indication of the ability of the timber to withstand challenging conditions.

Timber flooring will shrink or swell according to the species used, the installation environment and moisture content. Specifiers will want to know the percentage of dimensional change resulting from exposure to temperature and/or moisture changes. As shrinkage does not occur in a uniform manner, the rates of shrinkage for the length and width of the wood should be considered. Knowing these characteristics enables specifiers to assess suitability for a particular application.

Timber flooring is often supplied within a moisture content range of 9% to 14% (as provided by Australian Standard AS2796). If flooring is laid in a most environment (expected average moisture content of 12.5% to 15%), future expansion should be accounted for and the timber should be acclimatised.5 Shrinkage should be accounted for in dry environments (expected average moisture content of 8% to 10%) and acclimatisation is required.6

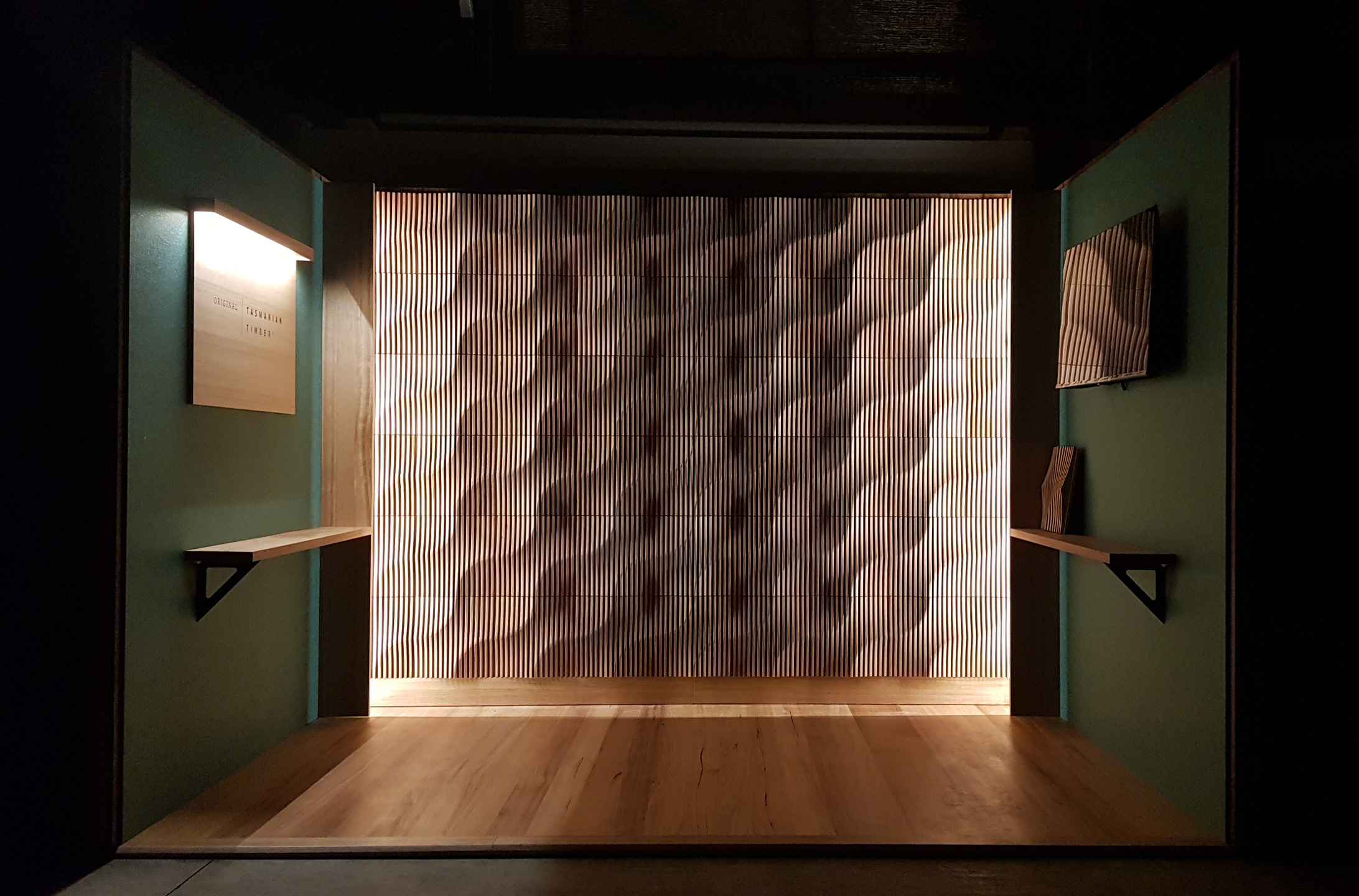

Tasmanian Oak

The Premier Hardwood for Flooring Applications

Sturdily withstanding the wear and tear of generations, Tasmanian Oak has been the flooring of choice in Tasmania and beyond for more than a century. Designers and specifiers prefer Tasmanian Oak because of its stability and reliability. Tasmanian Oak is a strong timber, easy to work, and renowned for its stability in flooring applications, giving performance that few other species can match.

Tasmanian Oak is light in colour, varying from straw to reddish brown with intermediate shades of cream to pink. It is recognised for its excellent staining qualities, which allow ready matching with other timbers, finishes or furnishings. It works extremely well and can be used in all forms of construction as scantlings, panelling and flooring, and can be glue-laminated to cover long spans.

About Tasmanian Timber

Tasmania’s biodiversity and verdant forests make it the ideal environment for strong, high quality timber to grow in: a significant portion of timber used for interior design, furniture, and structural purposes in Australia can be traced back to Tasmania In recognition of the vital role that Tasmanian timber plays in supporting sustainable local industries in Australia, the Tasmanian Timber Promotion Board seeks to educate designers and specifiers on the broad potential of timber and its many unique characteristics. Grown locally and sustainably, Tasmanian timber is processed to the highest standards, and backed by the technical support of Australia’s leading timber experts.

References.

1. United States Department of Agriculture. “Wood Handbook: Wood as an Engineering Material.” USDA. https://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr113/fplgtr113.pdf (accessed 28 March 2021).

2. Brisbane’s Finest Floors. “Australian Timber Hardness Table: Which Is The Toughest?” Brisbane’s Finest Floors. https://www.brisbanesfinestfloors.com.au/ latest-advice/australian-timber-hardness-table-which-is-the-toughest (accessed 28 March 2021).

3. Parquetry Flooring Company. “Janka Rating & Floor Durability.” Parquetry Flooring Company. https://www.pfc.com.au/janka-ratingfloor-durability (accessed 28 March 2021).

4. Lifewood Timber Flooring. “What is Janka Rating?” Lifewood Timber Flooring. https://www. lifewood.com.au/timber-floor-durability-janka-hardness-test (accessed 28 March 2021).

5. Housing Industry Association. “Moisture content and timber floors – getting it right!” HIA. https://hia. com.au/regional-news/vic/timber-floors-moisture (accessed 28 March 2021).

6. Ibid.