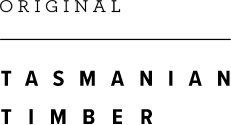

Decorative Veneers

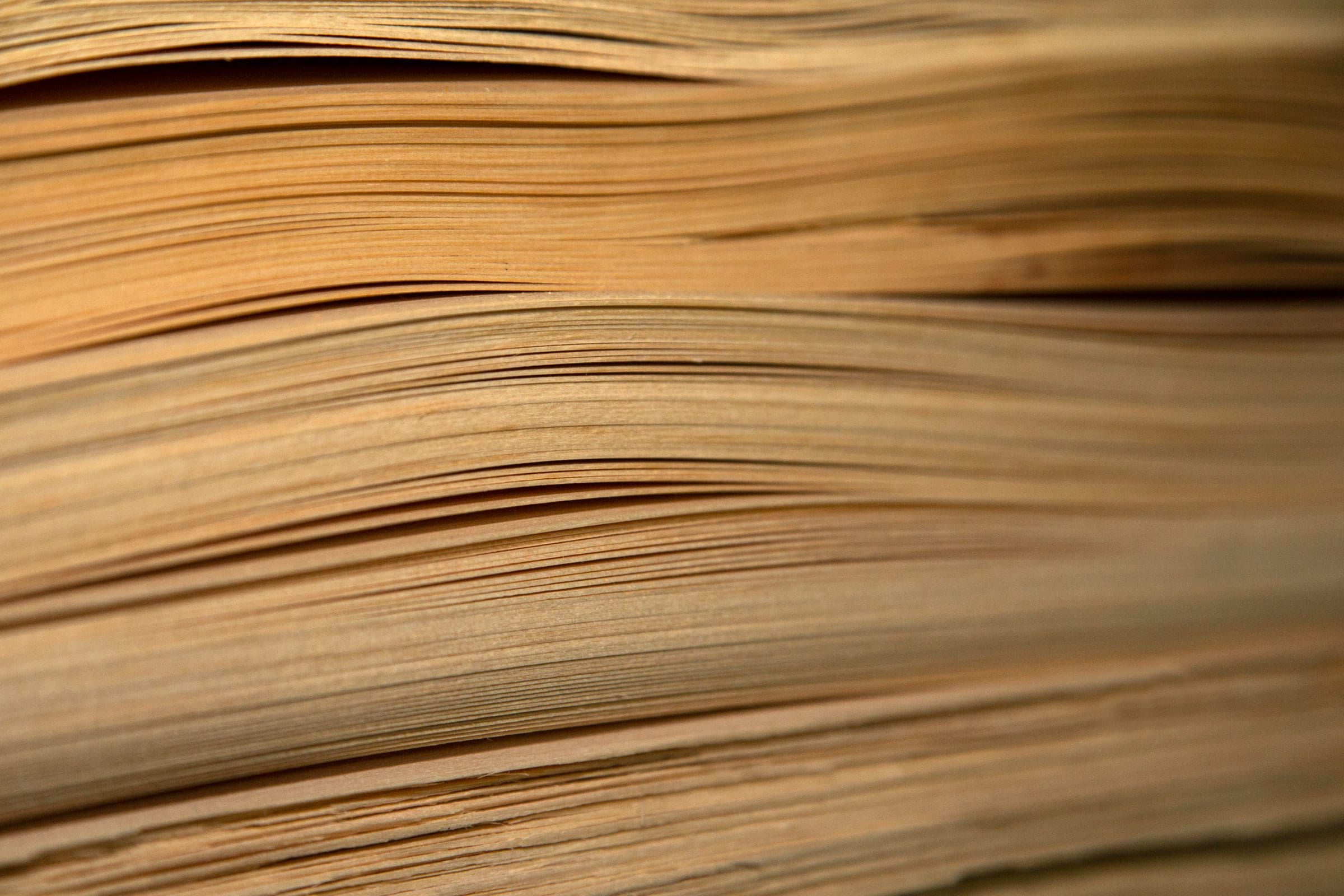

Veneering is an ancient technique that allows the desirable colour and textures of a large piece of timber to be spread over a much greater surface of a furniture, joinery or lining element. During the process, the larger piece of timber (or flitch) is either sliced or peeled into thin slices or veneers. These are then dried and sorted before being assembled and applied to a substrate or directly to the element.

Decorative wood veneers highlight the natural beauty of the timber. The appearance of the grain in the veneer results from the timber’s natural character and the direction in which the veneer was cut relative to the growth rings in the piece. When it is completed, the veneered item has the appearance as solid wood and provides an economical way to use the available timber resource, especially those species that may be rare, expensive, or otherwise impractical to use in timber solids.

Sliced decorative veneers are manufactured in Tasmania from a range of species and are supplied as veneer leaf, veneer sheets and veneered board, often with matching solid timber.

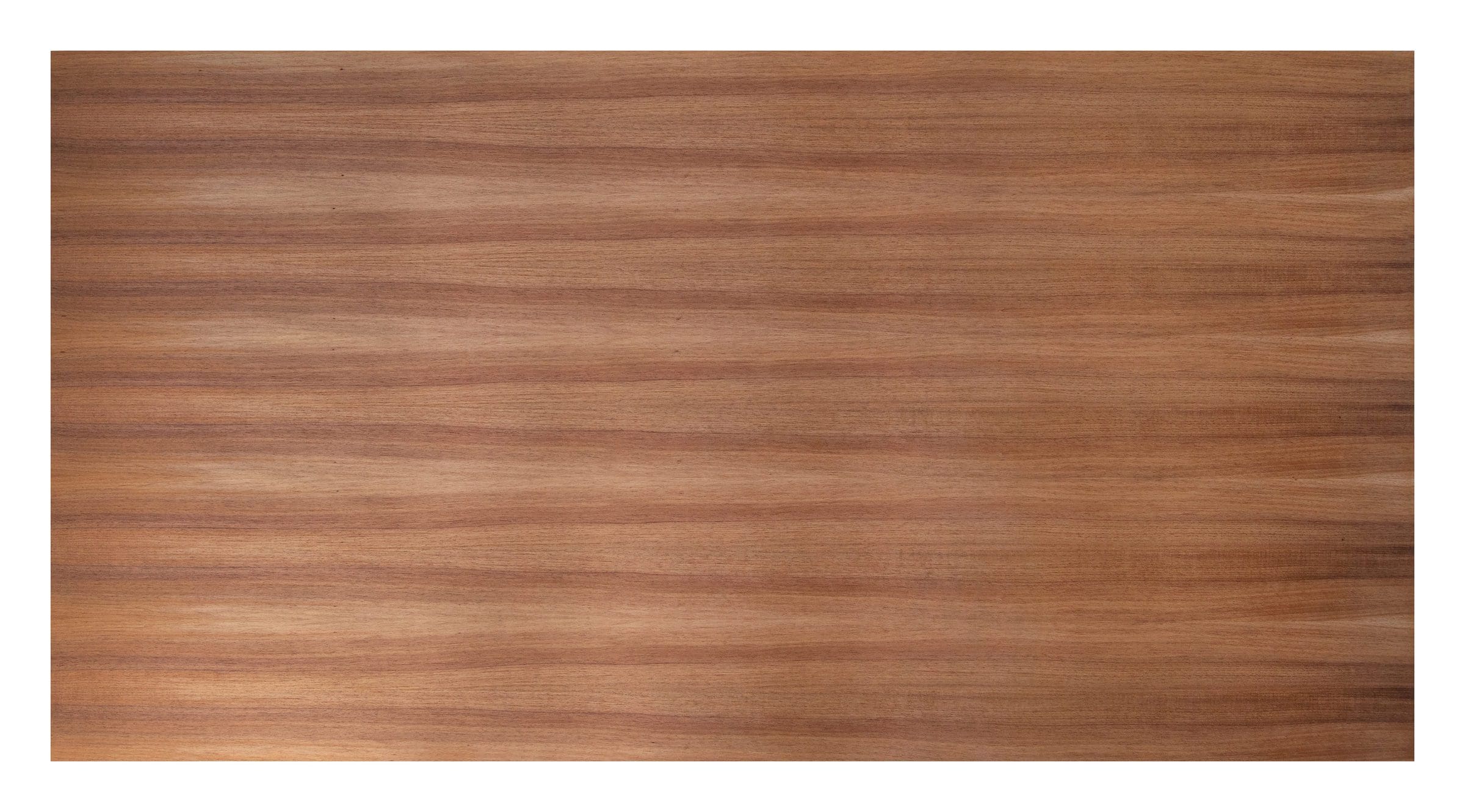

Veneer Leaf and Sheets

The piece of veneer sliced off the flitch and dried in called a leaf, and when stacked in consecutive order, the assembled leaves form a bundle. Bundles of veneer from a single flitch or log or individual leaves can be supplied in several widths and lengths for applications such as inlay, craft work and other veneer uses.

Veneer sheets are assembled from veneer leaves glued on their edge and formed into a sheet of the desired size. As the source and arrangement of the leaves in the sheet influence its appearance considerably, various standard assembly options are available, such as slip matched, book matched or mis matched sheets. Veneer sheets are supplied to joiners and other fabricators for inclusion in various joinery or lining elements.

Veneered Panels

Veneered panels are assembled by factory gluing veneer sheets on both sides of a solid substrate such as MDF and plywood. These panels generally have a preferred ‘face’ veneer on one side and less valuable ‘back’ veneer of the same species on the other. Both are necessary to maintain the board’s stability.

These panels can then be supplied with matching veneer leaf and solids to joiners and other fabricators for inclusion in a range of joinery or lining elements.