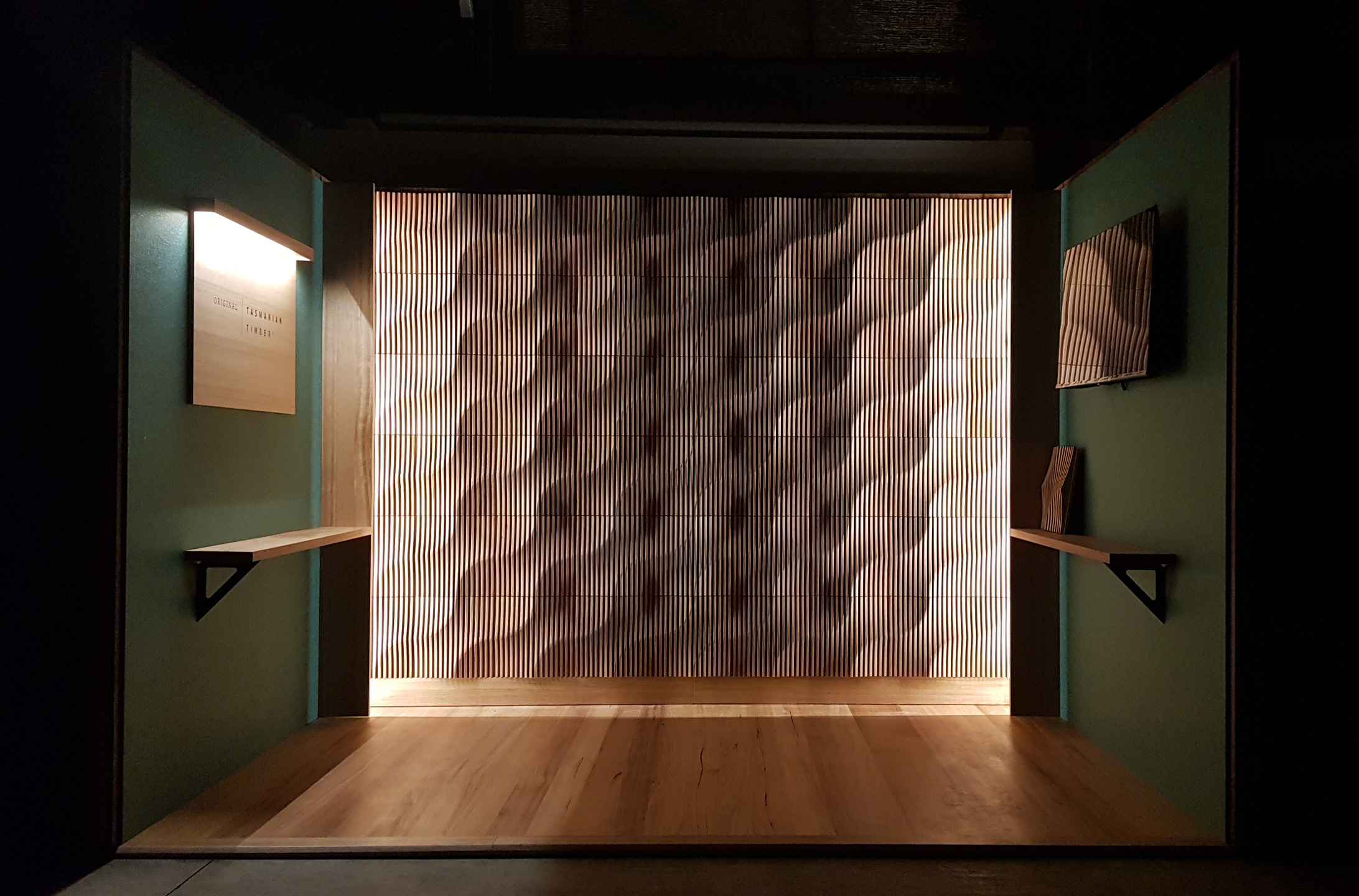

From log to LOGR, new technology allows Tasmania’s harvested timber to be tracked in real-time

The evolution of forestry practices has greatly evolved over the last decade. From investing in research and technology to building sustainable communities, to harvesting reclaimed timber from the bottom of a remote lake, to studying the density of plantation grown timber for potential new uses, innovation has exploded across Tasmania’s forestry sector. The state’s forestry suppliers and companies are employing the most innovative systems and processes to ensure efficiency from tip to toe, all with the technology to prove it.

One of these leaders in innovation is SFM Environmental Solutions, a leading provider of independent plantation management across Australia. SFM offers fence to fence management of commercial forestry estates, harvesting logistics solutions, market options and independent advice to a wide range of forest-based projects. Implementing a new software platform has elevated their chain of custody tracking giving their customers peace of mind- in real time.

The weigh of the future

LOGR is a haulage and weighing solution that simplifies tracking of trucks through its mobile app, eliminating the use of paper dockets and data entry allowing data to be shared with forestry companies, its contractors and customers, instantly. LOGR consists of a cloud-based administration dashboard and companion mobile app for drivers transporting timber, and a solution suite that assists in the management of transporting forestry products from collection to delivery.

SFM’s Finance Manager and Production Coordinator Tammy Price was the lead on implementing the new technology and says the new software solution has transformed the way they look at their supply chain.

“LOGR replaces the old paper docket system so all interested parties can keep track of what’s being harvested and transported. A driver creates a docket at the start of their route and real-time figures and data are made available along their route, all the way to their final destination. We can see how many trucks we have on the road at any given time, where they are and what they’re carrying,” explains Price.

Having the software built into their existing database by a local design company in May, Price says it’s been a smooth and speedy transition.

“We’ve been using LOGR for six months, and the access to real-time data has been a huge benefit to us and our customers. We’ve eliminated all paper so the issue of not being able to read handwriting, losing dockets or confusion around payments has been eliminated. Before, it could have taken almost a half a month for processing and now it can be completed within a day,” says Price.

Being able to track each truck has also help improve their chain of custody.

“Our chain of custody is much more rigorous now. We can tie down any information that we’re after with the click of a button. If someone wants to know where a truck is or what roads they took to get to their final destination, we can track that.”

While SFM is new to using this technology, Price says the industry only continues to adapt and change as new technologies become available.

“I think that there are a number of forestry businesses that are going to start to go down this kind of path, using systems that allow for data to be collected in real-time. It really is the way forward.”