Hydrowood are not your normal timber processors. They are treasure hunters.

When the Reece Dam was built across the Pieman River in 1987 as part of Hydro Tasmania’s hydroelectric power scheme, a valley containing great swathes of forests was flooded. Twenty-five years later the grey, dead trees stood like ghosts in the dark, tannin rich lake. This is where Hydrowood’s story begins.

A decade ago Andrew Morgan and David Wise, forest estate managers and entrepreneurs, began talking about the possibility of salvaging the wood from the flooded lake. David, a pilot, had seen the tops of the dead trees as he flew over Lake Pieman, and that started the conversation. Andrew was interviewed for the Original Thinkers Podcast about the origin of this pioneering company, and how much specialty timber could be recovered from Australia’s hydro lakes.

“Until we asked the question, ‘Couldn’t we potentially salvage them and turn them into beautiful timber?’ From that kernel of the idea we went through a feasibility study, tested the material and the material was sound.”

The trees were lost forever, submerged in very cold, dark tannic waters. The cold water, the lack of UV penetration and the anaerobic environment meant that bacteria was not breaking down the wood. Once recovered from the depths of the lake, the trees needed to be dried and milled. The University of Tasmania’s Centre for Sustainable Architecture with Wood helped Hydrowood devise a system for each of the six species that are submerged in the lake, and Andrew says the research is still continuing to this day.

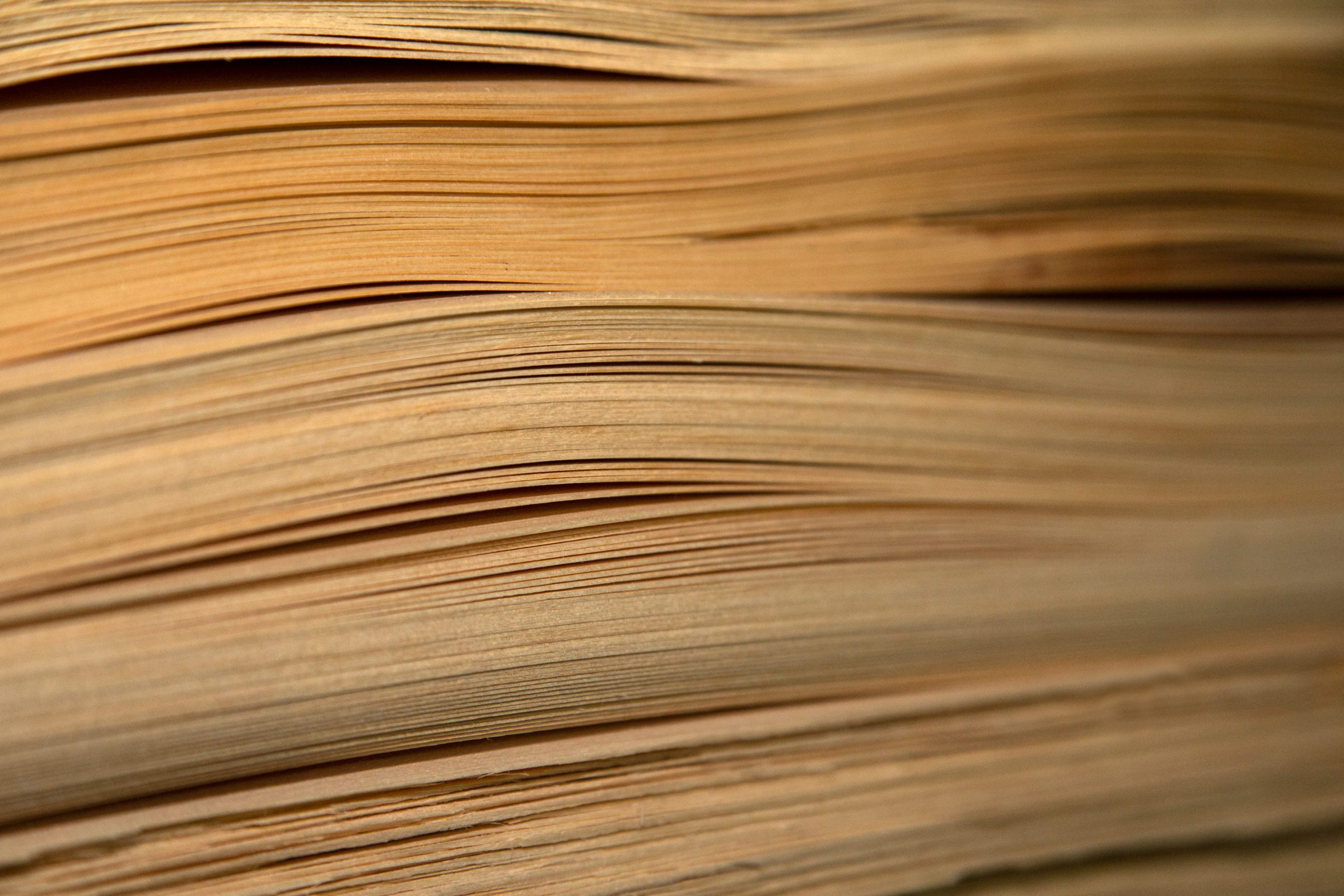

“We’ve gone out very broad in terms of our product offering. We’ve tested various markets. We’ve cut it for veneer. We’ve cut it for furniture. We’ve cut flooring. We’ve cut panelling and wall linings. And we’re still testing where those markets are. And we continue to test performance (for QA) because, architects, when they’re specifying a product, want confidence that that product will perform.”

The species reclaimed from the lake include the richly red coloured Tasmanian Myrtle, Tasmanian Oak, Blackwood, Celery Top Pine, Sassafras, Black Hearted Sassafras and the precious Huon Pine, revered globally for its buttery characteristics and workability.

One of the world’s first underwater forestry operations

The beauty and versatility of the timber and the timber products is one of the factors in Hydrowood’s success. The other is the story. As one of the world’s first underwater forest operations, the unique extraction makes Hydrowood timber truly unique. The story of a lost forest reclaimed has captured the imagination of architects, furniture makers and builders throughout Australia and internationally.

The difficultly of reclaiming the timber from the depths of Lake Pieman, and the ingenuity of the founders, led to the building of a custom barge designed to carry a 45 tonne excavator. The barge manoeuvres the excavator to an area of the lake, where the excavator reaches down into the depths, cuts the base and pulls it back up to the surface. It is only here they they can see what species they have harvested.

“So it’s treasure hunting. Whenever we take people to the lake they’re captivated. There’s mystique to that reveal. So as that tree comes up, it might be a beautiful blood red Myrtle or it might be a Huon Pine or it might be a Celery Top Pine. We extract a number of different species, so there’s always that anticipation of what’s it going to be next. People can sit there for an hour or two hours just quite happy watching trees being harvested. It’s quite an amazing experience.”

How much timber is in Tasmania’s Hydro lakes?

When asked how much timber is potentially in Lake Pieman Andrew explains that there is plenty more timber to be harvested:

“We think there’s somewhere around 60,000 cubic meters of sawn log left in that one lake, and we’re in discussions with Hydro Tasmania at the moment about other lakes that we could access. We’re talking about a few hundred thousand cubic meters of sawn log. With our current rates of harvest using one machine, we can produce 8,000 to 10, 000 cubic metres of saw log a year.”

Hydrowood timber has been used in some beautiful projects, from John Wardle Architect’s stunning Limestone House, to the Fusilier Cottage, the redevelopment of Hobart’s Parliament Square and Brodie Neill’s extraordinary ReCoil table. To hear more of Hydrowood’s Story listen to Andrew Morgan on the Original Thinkers Podcast here.