Why Tasmanian Oak flooring should be part of your next home instalment

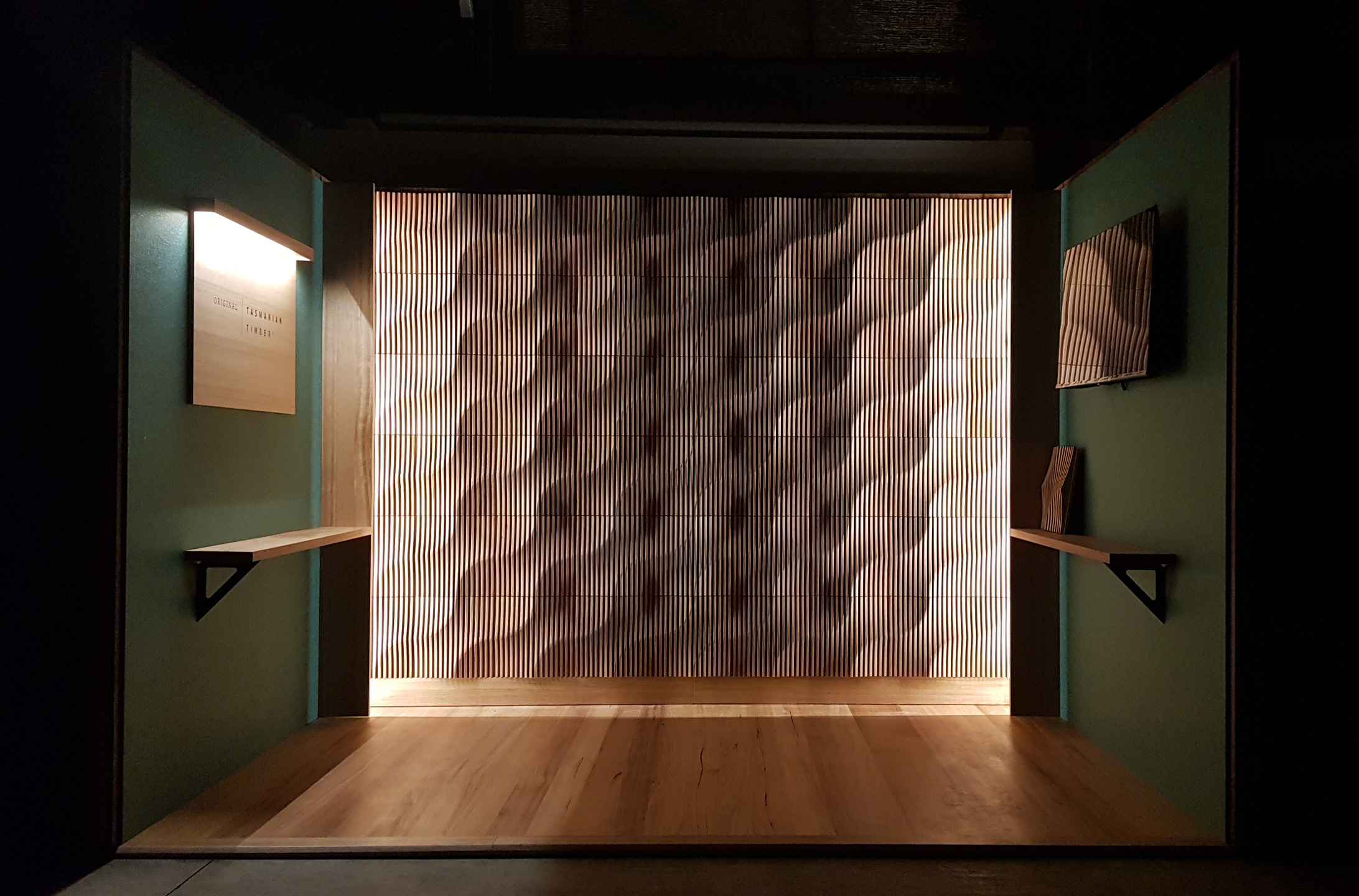

Specifying, building or renovating? When it comes to stability, reliability and striking appearance for timber flooring, you can’t look past Tasmanian Oak. Tasmanian Oak is a popular interior timber choice, be it for panelling, furniture or flooring. Warm, dense and recognised for its excellent staining qualities, this highly resilient timber gives off a smooth, lustrous finish.

Tasmanian Oak took out the Overall Winner Floor of the Year at the 2019 Australasian Timber Flooring Association (ATFA) Awards. As a flooring product, it’s widely available from distributors across the country in a variety of widths and products, including engineered flooring, solid and overlay.

Below are some of the main benefits of using Tasmanian Oak, the flooring timber of choice.

Stability champions hardness

Because of its stability and reliability, Tasmanian Oak has been used as a flooring material for over a century and continues to be in strong demand by architects and builders today. Just ask renowned designer-marker Jon Goulder who highlighted Tasmanian Oak for its incredible torsion.

“Its ability to stay straight is unmatched,” he said.

“I have never come across a timber that has the stability that Tasmanian Oak possesses.”

Timber expert Michael Lee, GM Cusp Building Solutions and previously Technical Officer at the Centre for Sustainable Architecture with Wood at the University of Tasmania says that the stability of Tasmanian Oak makes it a premium product and places the material in the upper echelons of the flooring market.

“[CSAW] look at a lot of Tasmanian Oak floors, many of them in commercial applications,” he said.

“If issues in a Tasmanian Oak floor ever arise, it’s very rarely the timber product that’s the issue, with the problem likely caused by an external factor.”

When it comes to the hardness rating of different flooring timbers, the Janka hardness scale is largely used by the timber flooring industry. However, Lee says stability in flooring is much more important than hardness. Tasmanian Oak is a mix of three species and the Janka rating is based off the lowest density species – E. Regnans. However, only a very small percentage of Tas Oak is made up of E. Regnans, which is a much softer wood than the E. Obliqua and E. Delegatensis.

“The bulk of the Tas Oak mix is now E. Obliqua which would actually sit somewhere between a six and a seven on the Janka scale, which is quite a good commercial grade of hardness,” says Lee.

“In my opinion, Tasmanian Oak is as good of a product as any, especially in a residential or sensibly detailed commercial environment.”

Easy application and cost-effective

Hobart architect Kate Symons will opt to use Tasmanian Timbers whenever she can. Tasmanian Oak was selected for much of the East Shelly Extension’s internal timber touches, including the flooring, veneer cabinetry, joinery, white painted lining boards, and solid kitchen bench top.

“Tasmanian Oak is accessible, joiners find it easy to work with, it’s cost-effective, versatile and renewable,” she said.

“I’ve been using it throughout my career and will continue to encourage my clients to use sustainable materials such as Tas Oak in projects going forward.”

An available resource

Founding Director of Preston Lane, Daniel Lane, says Tasmanian Oak is their go-to timber due to its aesthetic appeal, workability, and availability.

“Tasmanian Oak is obviously a hardwood, but it doesn’t behave as stubbornly as other hardwoods can and is easy to work,” he said.

“We’ve used Tas Oak not only for flooring but for doors, windows, light fixtures and occasionally externally as well.

“Tasmanian Oak has a beautiful, fine grain and blends in easily with other materials.

“The fact that it’s also always readily available and in the sizes that we need, make it easy to incorporate into a design, knowing that we can always get our hands on exactly what we want.”

A major national supplier of Tasmanian Oak, Britton Timber’s Shawn Britton said a network of sustainable, local resources, combined with a substantial stock holding of Tasmanian Oak, meant peace of mind for his customers.

“We’re gearing up to cater for that (heightened demand for timber) so we can offer a seamless supply chain, so we’ve got our product situated in locations around the country,” he said.

“It can move from manufacturing in Tasmania to our warehouses to commercial or domestic applications within days as opposed to weeks or months for imported products seamlessly.”

Sustainably sourced

Designing smaller dwellings is one part of Architect Andrew Simpson’s philosophy behind sustainable design. The Y House along the Great Ocean Road is a testament to this ethos and the use of Tasmanian Oak. However, Simpson also explains why he uses locally sourced timber as much as he can.

“We have a massive country filled with species of timber unique only to here,” he said.

“The timber industry in Australia has improved with time which makes sourcing sustainable timber that’s also locally sourced a great choice compared to something that’s been imported.”

Want to be assured that Tasmanian Oak is grown and harvested sustainably and meets Australian Standards? Look no further than the Tasmanian Timber Quality Assurance Program, Responsible Wood and Chain of Custody Certification.

The Quality Assurance Program assesses nominated products for Australian Standards compliance through a quarterly mill audit. In addition, all suppliers that carry the Quality Assurance Endorsement hold Chain-of-Custody, and Responsible Wood accreditation. This means that their products are certified to come from forests with sustainable forest practices.

Tasmanian Oak and other Tasmanian Timbers are sourced from forests that are sustainably managed, independently audited and certified to an internationally acclaimed standard.

Want to know more?

Tasmanian Oak is readily available from our certified suppliers.

For more information, support, or to request a quote for Tasmanian Oak flooring, mouldings, veneers, interior and structural products contact the Tasmanian Timber Expert Helpline on 1300 041 766 or via the webform.